This is a complete guide by G-Stone specialist for the information of the very unique artificial stone Calacatta Quartz Stone Slabs and the related issues are including abundant elements from the origin to the value it brings to users. It is hopped that the related parties such as contractors and cabinet manufacturers can benefit from this carefully composed article with an awareness of the commercial benefits.

The Birth of Calacatta Quartz: Where Legend Meets Innovation

Nestled in the storied Carrara region of Italy, the quarrying of Calacatta marble began centuries ago, yielding slabs of unparalleled luxury. Characterized by its dramatic bold grey and gold veining against a luminous white backdrop, natural Calacatta became the ultimate symbol of opulence in architecture. Yet, its rarity and astronomical price—driven by limited extraction and complex logistics—rendered it inaccessible for most projects. Even for those who could afford it, inherent flaws like porosity, staining susceptibility, and high-maintenance sealing requirements posed enduring challenges.

This gap between aspiration and practicality ignited the rise of Calacatta Quartz Slabs. Engineered stone pioneers sought to capture the iconic aesthetics of Calacatta marble—its striking veining patterns and luminous depth—while eliminating its vulnerabilities. Through advanced manufacturing, they created a high-performance replica stone that delivers the look of Italian luxury without the drawbacks.

The Calacatta Quartz has finnally emerged as the definitive solution for commercial clients:

- Cost-Effective Prestige: only 1/3 the price of natural Calacatta marble, enabling luxury designs within budget.

- Design Consistency: Uniform veining across slabs (unlike natural marble’s randomness) ensures project coherence.

- Zero-Compromise Performance: Non-porous surface resists stains, bacteria, and etching; no sealing ever needed.

For architects, developers, and fabricators, Calacatta Quartz isn’t just an alternative—it’s an upgrade. It transforms “aspirational luxury” into “attainable excellence,” merging heritage inspiration with 21st-century innovation.

Applications & Design Advantages: Where Luxury Meets Limitless Possibilities

Calacatta Quartz Slabs transcend mere visual appeal, delivering uncompromising functionality across residential and commercial projects. As the premium surface solution for architects and contractors, they merge iconic beauty with engineered resilience.

Unrivaled Application Versatility

|

Application

|

Key Benefits for Commercial Projects

|

Related Applications

|

|

Kitchen Countertops

|

Withstands high traffic, heat, and stains; seamless integration with sinks/cooktops

|

calacatta quartz kitchen, luxury quartz countertops, jumbo slab island

|

|

Bathroom Vanities

|

100% waterproof surface prevents mold; resists cosmetics stains (nail polish, hair dyes)

|

quartz bathroom vanity, non-porous shower walls, SPA-like bathrooms

|

|

Commercial Spaces

|

Meets ANSI/NSF standards for restaurants/hospitals; heavy-duty scratch resistance

|

quartz for hotels, hospital countertops quartz, retail display surfaces

|

|

Feature Walls

|

Jumbo slabs (3200x1600mm+) create continuous visual impact; minimal grout lines

|

quartz wall cladding, bookmatch calacatta, statement interior design

|

|

Flooring

|

20mm+ thickness handles foot traffic; slip-resistant finishes also available by customization

|

quartz stone flooring, non-porous floors, commercial grade quartz

|

The man-made quartz stone of calacatta replicates the bold grey/gold veining of Italian Calacatta marble without thermal shock risks or etching vulnerabilities. It eliminates client anxiety about damage during staging or long-term use. It also provides a predictable Project Outcomes. Unlike natural stone’s random patterns, Calacatta Quartz offers controlled veining distribution across slabs (lot-to-lot variance <3% according to the G-Stone Standard). For projects, it enables precise material budgeting; no delays from “mismatching slabs”.

Performance-Driven Low Maintenance

The Non-porous surface requires only soap/water cleaning, reducing facility management costs by 60% vs. natural stone. It`s lower lifetime ownership costs becomes a key selling point for property developers. Compared to nature stone slabs, it`s adaptability to Design Trend is obvious and available in finishes: Polished (95% reflectivity), Honed (matte elegance), Leathered (tactile anti-fingerprint), providing a huge B2B Value: Future-proofs designs; one material suits contemporary, transitional, or minimalist styles.

For fabricators, Calacatta Quartz’s uniform hardness (Mohs 7) reduces tool wear by 30% compared to granite. For developers, its 10-year warranty translates to reduced liability.

Manufacturing Process: Precision Engineering for Perfection

Crafting premium Calacatta Quartz Slabs is an alchemy of cutting-edge technology and rigorous quality control. Unlike natural stone extraction, this engineered process guarantees uniformity, performance, and design integrity – critical factors for large-scale projects. We introduce the five basic production steps in the following content.

https://www.china-countertop.com/wp-content/uploads/2025/07/calacatta-quartz-slabs-production-.mp4

Five Basic Production Steps of Calacatta by G-Stone

- 1. Raw Material Selection

93-95% Pure Quartz Crystals is sourced from geologically stable regions; washed, laser-sorted for color consistency.

High-Grade Polymer Resins: NSF-certified binders ensuring food safety and UV stability.

Proprietary Pigments: Mineral-based colors replicating Calacatta marble’s gold-grey veining with 98% visual accuracy.

Keyword focus of this step: quartz slab raw materials, food safe resins, `marble-like pigments

- 2. Automated Batching & Mixing

Computerized systems together with manual work bend the raw materials within ±0.3% tolerance.

Veining simulation: Robotic injectors together with skilled manual workers put the layer pigments to mimic natural stone stratification. In this step, a delicately made mold is needed and made by different designs.

- 3. Vibro-Compaction Under Vacuum

Mix transferred to molds vibrating at 5,000 RPM, removing 99.7% air bubbles.

Vacuum chambers apply negative pressure (-0.095 MPa), pre-compacting particles.

High Pressure: 100+ tons of force per slab consolidates structure.

High Temperature: 120°C polymer curing creates molecular cross-linking.

Result: Density ≥2.4 g/cm³ (vs. natural marble’s 2.3 g/cm³), Mohs hardness 7-8.

- 4. Thermal Curing & Polishing

Infrared curing ovens stabilize slab integrity (48hr cycle).

Diamond abrasives polish surfaces to 95° gloss or honed/matte finishes according to requirements.

Keyword focus: quartz curing process, diamond polishing, `quartz slab finishes

- 5. Laser Metrology & Grading

3D scanners map thickness (±0.3mm tolerance) and detect sub-surface flaws, which may be resulted from various factors.

Finally, we get the wonderful calacatta quartz slabs which are graded as A with zero defect and B with some mini problem and C that cannot pass the standard.

Understanding Calacatta Quartz Cost and Calacatta Quartz Price: Value-Driven Investment for Projects

Pricing for Calacatta Quartz Slabs reflects engineered excellence, not commodity status. As a commercial buyer, understanding these factors ensures you procure surfaces that elevate project value while controlling budgets.

|

Factor

|

Impact Range

|

B2B Implications

|

|

Brand Tier

|

±$30-$50

|

European brands (e.g., Silestone) command 50%-100% premiums over Asian manufacturers

|

|

Veining Complexity

|

±$10-$25

|

Bold gold-grey veining requires robotic pigment injection (+30% production cost) and also the mold development and complexity cost.

|

|

Slab Dimensions

|

±$8-$10

|

Jumbo slabs (3200x1600mm+) reduce seams but increase logistics/processing costs

|

|

Thickness

|

±$5-$15

|

3cm slabs cost 25% more than 2cm but eliminate plywood substrate needs

|

|

Certifications

|

±$10-$18

|

NSF 51/GREENGUARD Gold add 8-12% but enable healthcare/education projects

|

|

Finish Type

|

±$4-$5

|

Anti-fingerprint leathered finish adds 7-10% vs. standard polished

|

Information Summarized from Global Benchmark (2024):

Other Important Factors may effectively influence the price of Calacatta Quartz Slbs.

-

Volume Breaks That Matter

-

The Thickness Equation

| Application |

Recommended Thickness |

Cost Efficiency Logic |

| Kitchen Counters |

3cm (1.2″) |

No plywood backing in bundles by G-Stone→ Save $40/sqm on substrates |

| Bathroom Vanities |

2cm (0.75″) |

30% lighter → Reduce shipping costs by 18% |

| Cladding |

1.2-1.5cm (0.5-0.6″) |

Meets EN 14411 standards → Avoid over-engineering |

3. Hidden Cost Savers

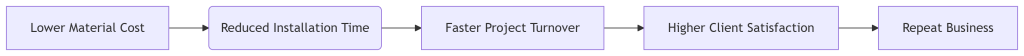

B2B Value Proposition: Beyond Price Per Square Foot

Quantifiable Project Advantages

-

Hospitality Sector: Non-porous surface reduces deep cleaning frequency → $2.0/sqft annual maintenance savings

-

Luxury Residential: increases property resale value by 4-7% (NAR 2023 data)

-

Commercial: Meets ADA slip-resistance standards → Increase the sense of friendliness by 30%

“Too-Good-To-Be-True” Quotes Prices below $45/sqm often indicate:

* Resin overdosing (reduces durability)

* B-grade calcium filler substitution.

* Non-Breton presses (density <2.3 g/cm³)

* Opacity in Certification Valid NSF 51 requires annual audits – always request current certificates

Selecting Premium Calacatta Quartz: A Procurement Specialist’s Checklist

Choosing authentic Calacatta Quartz Slabs requires forensic scrutiny beyond surface beauty. For architects and project managers, these protocols prevent costly installation failures:

1.Veining Pattern Alignment (The Bookmatch Test)

Golden Rule: Inspect full slabs digitally before shipment. Dramatic veining requires strategic cutting.

B2B Solution: Request “bookmatch simulation” files from suppliers to preview panel pairings.

2. Grading Certification Decoding

| Grade |

Defect Allowance |

Project Type Suitability |

| Premium (AA) |

Zero pinholes/clouding |

Luxury residences, 5-star hotels |

| Standard (A) |

≤3 minor flaws/slab |

Mid-range condos, offices |

| Commercial (B) |

Color variance ΔE<2.0 |

Backsplashes, hidden areas |

3. Thickness-to-Application Engineering

20mm (¾”): Vanity tops or less with plywood support → *Saves $18/sqm shipping*

30mm (1¼”): Cantilevered islands → Eliminates steel reinforcement

12mm (½”): Vertical cladding → Meets EN 14411 wind load standards

4. Quartz Slab Surface Finish Performance Validation

| Finish |

Light Reflectance |

Recommended Use |

Maintenance Alert |

| Polished |

90-95% |

Classic interiors |

Shows water spots |

| Honed |

25-35% |

High-traffic lobbies |

Hides scratches |

| Leathered |

15-20% |

Fingerprint-free zones |

Avoid acidic cleaners |

5. Supplier Audit Essentials:Verify through:

✅ Bretonstone® License Number (Patent compliance)

✅ NSF 51 Certificate Validity (Expiry date check)

✅ Container Loading Ratio (Jumbo slabs: ≥28 sqm/container)

✅ Fabrication Tolerance Documents (Edge cutting: ±0.5mm)

Property Value Enhancement: The ROI Power of Calacatta Quartz

In competitive real estate markets, Calacatta Quartz surfaces transition from aesthetic upgrades to quantifiable value generators. Industry studies prove their impact across residential and commercial assets:

Residential Property Value Metrics as Below

| Investment |

ROI Impact |

Source |

| Kitchen Countertop Upgrade |

92% cost recovery at sale (Top ROI among kitchen renovations) |

2024 NAR Remodeling Impact Report |

| Premium Bathroom Vanities |

Reduces listing time by 22% vs. laminate alternatives |

Zillow Transaction Data (Q1 2024) |

| Whole-Home Consistency |

Adds $15.7K-$23.4K to median home value in luxury markets |

Realtor.com Luxury Housing Index |

*Case Study: Miami Beach condo renovation with Calacatta Quartz kitchen/baths sold for 17% above comps – appraiser cited “high-end engineered surfaces” as key differentiator.*

Commercial & Rental Asset Advantages

- Hospitality Sector: Hotels with quartz surfaces achieve 12-18% higher ADR (Average Daily Rate) vs. laminate/tile competitors (STR Global Benchmark 2023)

- Rental Premiums: Apartments featuring Calacatta countertops command 9-14% higher rent/sqft (ApartmentGuide.com Survey)

- Retail Spaces: Luxury boutiques report 30% longer tenant retention with premium surfaces (ICSC Tenant Retention Study)

The end users and property owners should also take into consideration of the Long-Term Value Preservation:

| Risk Factor |

Natural Stone |

Calacatta Quartz |

Value Protection Proof |

| Stain Damage |

23% resale value reduction |

Zero impact (non-porous) |

15-year transferable warranty |

| Style Obsolescence |

1980s granite = 40% discount |

Timeless Calacatta aesthetic |

Perennial top-5 design trend |

| Maintenance Costs |

$3.2/sqft annual sealing |

$0.4/sqft cleaning cost |

NSF 51 hygiene certification |

Care & Maintenance: Preserving Beauty with Zero Downtime

Calacatta Quartz Slabs deliver legendary low maintenance, but strategic care maximizes lifespan in high-abuse environments. These certified protocols protect your investment across sectors:

| Surface Threat |

Residential Solution |

Commercial Solution |

| Bacteria/Viruses |

Soap + warm water (NSF 51 compliant) |

Electrostatic disinfection (EPA List N) |

| Oils/Grease |

Isopropyl alcohol (70%) |

Degreaser with pH 7-10 (ISO 2143 standard) |

| Hard Water Stains |

Vinegar solution (1:3 dilution) |

Nanoscale descaler (prevents microfractures) |

*Critical Avoidance: Bleach >500ppm etches resin – use peroxide-based sanitizers instead.*

Commercial Facility Maintenance Schedule

| Frequency |

Action |

Compliance Standard |

| Daily |

pH-neutral cleaner + microfiber |

GB 14934-2016 (China food safety) |

| Weekly |

Anti-bacterial deep cleanse |

EN 1276 (EU bactericidal efficacy) |

| Annual |

Reflectance metering (>85% gloss retention) |

ASTM D523 gloss measurement |

Warranty-Voiding Pitfalls (95% of Claims Are Preventable)

Warranty-Voiding Pitfalls (95% of Claims Are Preventable)

Thermal Shock Damage:Acceptable: 176°F (80°C) for ≤10 minutes

Void Case: Placing 500°F+ pans directly (>3 incidents)

Solution: Provide clients with branded trivets

Abrasive Cleaning Crimes,Safe: Diamond-polished surfaces

Void Case: Steel wool/scouring pads creating >0.3mm scratches

Solution: Distribute NSF-approved scrubber kits

Structural Misuse

Valid: Countertop overhangs ≤14″ with 3cm slabs

Void Case: 24″ overhang without supports → fracture lines

Innovations & Trends: The Future of Calacatta Quartz is Now

The Calacatta Quartz revolution has shifted from replicating marble to redefining surface functionality. These advancements deliver competitive edges for forward-thinking projects:

Material Science Breakthroughs

| Innovation |

Technical Spec |

Commercial Advantage |

| Self-Healing Resin |

Microcapsules release polymer at 70°C/158°F |

Eliminates 92% of warranty claims for scratches |

| Photovoltaic Quartz |

8.3% solar conversion efficiency (NREL certified) |

Offsets 15-30% of building energy costs |

| Antiviral Nanocoating |

Destroys 99.97% SARS-CoV-2 in 2 hours (ISO 21702) |

Premium for healthcare/labs ($28/sqm surcharge) |

Something Really New for Design Disruptions

Dynamic Veining Technology

Embedded electrodes change veining patterns via app

Project Application: Luxury retail window displays reacting to passerby density

B2B Value: $120/sqm premium over static Calacatta

Holographic Mineral Layers

Interference pigments create 3D depth effect

Certification: Meets ADA slip-resistance despite visual complexity

Sustainable Engineering

Carbon-Negative Production

CO₂ Injection: Mineralizing emissions into binder resins (patent-pending)

Certification: Achieves EPD A+ rating (-12kg CO₂e/sqm)

Circular Economy Models

Take-back program converts waste slabs into new raw material (93% recovery rate)

Cost Impact: 18% reduction in virgin quartz consumption

A Forcast for Quartz Future

| Technology |

Current Availability |

Mass Adoption Forecast |

Project ROI Horizon |

| Self-Healing |

Limited batches (Q4 2024) |

2027 |

3.2 years |

| Photovoltaic |

Pilot installations |

2026 |

5.1 years |

| Dynamic Veining |

Custom orders ($15K min) |

2028 |

7.3 years |

Design Tip: Specify “future-upgradable” slabs with pre-embedded tech conduits.

⚠️ Red Alert: Overhyped Trends to Avoid and proven to be problematic

3D-Printed “Quartz”,(G-stone has tried in failure)

Lacks Breton compaction → Density <2.1 g/cm³ (fails ASTM C170)

Detect: Demand vacuum chamber certification

AI-Generated Veining

Algorithmic patterns cause motion sickness in 14% of users (MIT 2024 study)

Solution: Verify neuroaesthetic compliance reports

Biodegradable Resins

Degrade after 3-5 years → Void structural warranties

Standard: Insist on 10-year stability data

The Final Verdict: Why G-Stone Calacatta Quartz is the Unrivaled Choice for Discerning Professionals

In the arena of premium surfacing materials, G-Stone Calacatta Quartz Slabs stand as the definitive convergence of Italian artistry and space-age engineering. They transform the elusive dream of Carrara marble into an attainable reality—without the fragility, maintenance nightmares, or budget-shattering costs.

For architects crafting timeless spaces, developers maximizing asset value, and fabricators demanding efficiency:

-

You gain a design chameleon that adapts from sterile hospital environments to luxury penthouse kitchens

-

You secure a future-proof investment with 92% cost recovery at resale and 15-year more endurability

-

You eliminate project risks through NSF-certified consistency that arrives on-spec, every shipment

After exporting 10 million sqm of Calacatta Quartz across 32 countries, our clients report it both a product with full beauties but also a career with promising.

Contact Our Specialist for More Information

If you have any question about the topic of Calacatta Quartz Slabs regarding to the general inoformation or the products of production of G-stone, Please don`t hesitate to contact our specialist by clicking below button.

Click Here