Cultured Marble: Engineered Excellence

Between Cost-Performance

In our virtue showroom, we presents to you more than 250 produced design of Cultured Marble Stone, please discover why our agglomerated marble stands out in quality, durability, and design flexibility

What is Cultured Marble ?

While commonly called "Gangshi" in China, this premium surfacing material is known internationally by several technical names. Understanding these terms helps specify the exact product characteristics,and you can tell the difference even from the definition of the names:

*Agglomerated Marble - The most accurate technical term, referring to the manufacturing process where natural marble aggregates (90-95%) are bonded with polymer resins (5-10%) under vacuum compaction.

* Engineered Stone - A broader category including quartz surfaces. Unlike quartz, true agglomerated marble uses marble fragments as primary raw material.

*Reconstituted Marble - Emphasizes the decomposition of natural marble waste into high-value slabs, highlighting sustainability.

*Cultured Marble - Primarily used in North America for cast polymer products with lower stone content (70-80%), differing in density and applications.

What Cultured Marble Designs ?

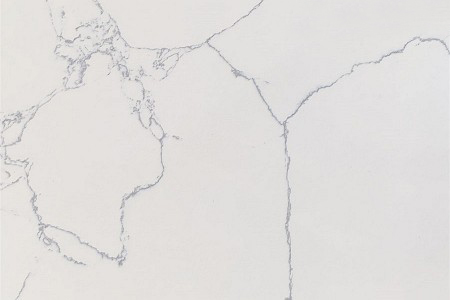

White Cultured Marble

Carrara Cultured Marble

Marble Look Cultured Marble

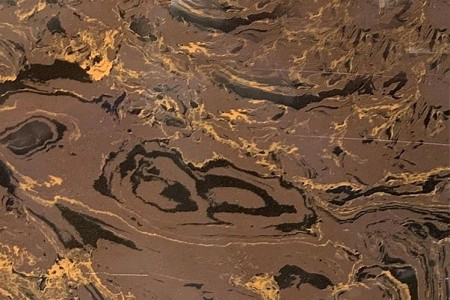

Granite Look Cultured Marble

Bold Veined Cultured Marble

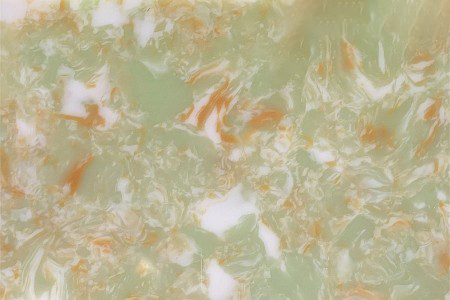

Jade-Like Cultured Marble

Cultured Marble Countertops

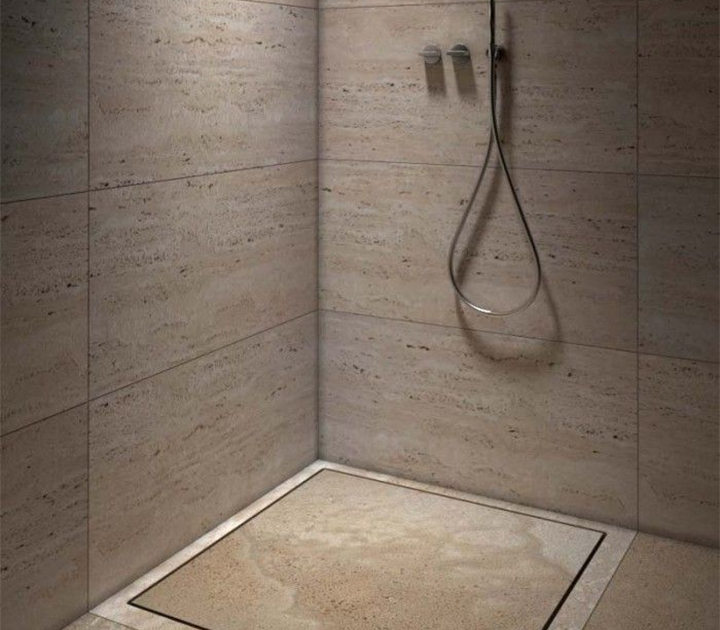

Cultured Marble Shower Walls

The Application of Cultured Marble

G-STONE cultured marble is a high-performance engineered stone that delivers exceptional value for manufacturers, contractors, and wholesalers in the building materials industry. Combining the aesthetic appeal of natural marble with superior durability, cost efficiency, and customisation options, it is an ideal solution for large-scale residential and commercial projects.

For B2B buyers seeking a competitive edge, cultured marble offers scalable supply, consistent quality, and design flexibility to meet diverse project requirements. Explore its key applications below to discover how it enhances profitability and client satisfaction.

Kitchen Countertops

Cultured marble kitchen countertops are a lucrative product line for fabricators and bulk suppliers due to their growing demand in residential and hospitality projects. Unlike natural stone, engineered marble offers uniform quality, reducing material waste and speeding up fabrication

Bathroom Vanity Tops

Cultured marble vanity tops are a top choice for hotel chains, apartment developers, and healthcare facilities due to their hygienic, moisture-resistant properties and design consistency. For B2B buyers, bulk orders of prefabricated vanity units streamline procurement and reduce project timelines.

Shower Room Walls

Cultured marble shower walls are gaining traction in commercial and multi-family projects due to their seamless installation and low lifetime maintenance. For contractors, large-format cultured marble panels reduce labor costs by minimizing cutting and grouting work.

Commercial Floors

Cultured marble flooring is a strategic choice for retail spaces, airports, and corporate lobbies where durability and aesthetics are paramount. Architects specify it for its slip-resistant variants, color consistency, and ability to mimic luxury materials at a fraction of the cost.

The Advantage of Cultured Marble

Cost-Effective

The cultured marble provides significant savings in material and installation costs. Bulk buyers benefit from consistent pricing and reduced waste, making it a smart choice for large-scale projects in hospitality and real estate development.

Durability & Longevity

Cultured marble is engineered for high resistance to scratches, stains, and impact, making it ideal for heavy-use areas like kitchens, bathrooms, and commercial floors.

Seamless Aesthetics

Available in a wide range of colors, patterns, and finishes, cultured marble can be tailored to match any architectural style. Prefabricated options (integrated sinks, vanity tops, and large-format panels) streamline installation, reducing labor costs for contractors and developers.

Low Maintenance

Unlike natural stone, cultured marble requires no sealing or special cleaners. Its non-porous surface resists mold, bacteria, and stains—ideal for hospitals, hotels, and high-traffic commercial spaces where hygiene and ease of upkeep are critical.

Customizable Designs

Cultured marble offers unmatched design flexibility, available in all colors, patterns, and finishes to match any architectural vision. Prefabricated options—like integrated sinks, vanity tops, and large-format panels—ensure seamless installation, reducing labour costs.

Production of Cultured Stone by G-Stone

Raw Material Mixing

Crushed natural stone (marble/quartz) is blended with high-performance polyester resin, pigments, and additives in precise ratios to ensure durability, color consistency, and desired texture.

Casting

The mixture is poured into moulding machines and vibrated to eliminate air bubbles and then pressed for a flawless grand cubic stone.

Curing & Hardening

The cast cube under controlled temperature and humidity, forming a solid, non-porous structure with high strength and stain resistance.

Cutting & Trimming

After curing, slabs are cut from cube, and edges are precision-trimmed to achieve uniform dimensions for seamless installation.

Surface Treatment

Automated polishing machines create a glossy, matte, or textured finish, enhancing aesthetics and ensuring a smooth, scratch-resistant surface.

Quality Inspection & Packaging

Each slab undergoes strict checks for defects before protective packaging, ensuring safe shipping for global B2B/B2C distribution.

Customisation of Cultured Stone

At G-STONE, we specialize in crafting premium cultured stone that perfectly matches your architectural and design requirements. Our advanced manufacturing process allows complete customization of colors, patterns, textures, and finishes—whether you need classic marble veining, modern solid hues, or unique artistic effects. We work closely with architects, developers, and homeowners to create bespoke solutions for countertops, vanities, wall cladding, and flooring. With state-of-the-art technology and skilled craftsmanship of more than 15 years experience, we ensure each piece meets exact specifications while maintaining the durability and low-maintenance benefits of engineered stone.

Beyond aesthetics, our custom cultured stone offers practical advantages for large-scale projects. We produce prefabricated modules with precision-cut edges, integrated sinks, and specialized profiles to reduce installation time and costs. Available in standard and oversized formats, our materials adapt seamlessly to commercial and residential applications. From hotel lobbies to luxury kitchens, we provide consistent quality with unlimited design flexibility. Contact us to discuss how our customizable cultured stone can elevate your next project with both beauty and functionality.

With decades of experience and exceptional flexibility, our factory specializes in supplying premium cultured marble for all types of construction projects. We seamlessly adapt to your requirements - whether it's custom sizes, unique finishes, or tight deadlines.Why not contact us today ?

Why Choose Us As Your Cultured Stone Manufacturer

For Architects & Designers:

Tired of compromising between aesthetics and functionality? Our cultured marble offers unlimited customization in colors, patterns, and finishes to bring your creative visions to life—without the high cost or maintenance of natural stone. Perfect for high-end residential and commercial projects, our engineered stone delivers consistency, durability, and design flexibility. Request samples today!

For Contractors & Developers:

Need durable, cost-effective materials that speed up installation? Our prefabricated cultured marble slabs and vanity tops reduce labor time and waste, keeping your projects on schedule and budget. Resistant to stains, scratches, and moisture, it’s ideal for high-traffic areas like hotels, kitchens, and bathrooms. Contact us for bulk pricing!

Homeowners & Renovators:

Want luxury surfaces without the hassle? Unlike natural marble, our cultured stone requires no sealing and is easy to clean—perfect for busy households. Choose from classic or modern designs to elevate your kitchen countertops, shower walls, or flooring. Get a free quote and transform your space!

FAQ on Cultured Marble Stone

What cost is the G-STONE cultured marble?

The Price of the current G-STONE cultured marble is around 10-20USD/SQM based on EXW trade term.

What are the technical specifications of your cultured marble?

Our premium cultured marble features: Mohs hardness: 4-5 (comparable to natural marble) Water absorption: <0.15% Flexural strength: ≥15MPa Thickness options: 12mm, 20mm, 30mm Maximum slab size: 3200x1600mm Ideal for high-traffic commercial applications requiring durability and consistency.

What project types is your cultured marble best suited for?

We've successfully supplied for: 500+ hotel bathroom vanity projects 200m²+ corporate lobby wall cladding Hospital laboratory countertops (antibacterial grade) Shopping mall flooring (slip-resistant version) University building facades (UV-resistant formula)

How does your cultured marble compare to natural stone for large projects?

Advantages for commercial use: 40% faster installation (pre-fabricated modules) 30% lighter weight (reduces structural load) Color consistency across batches Custom sizing minimizes waste 5-year commercial warranty available

What customization options do you offer for architects? We provide:

We provide: CAD/CAM precision cutting (±0.5mm tolerance) Integrated sink bowls (30+ designs) Edge profiles (12+ standard options) Matching accessories (backsplashes, etc.) Digital color matching service

What's your production capacity for bulk orders?

Standard lead time: 2-3 weeks for 500m²+

Maximum capacity: 10,000m²/month

Container loading: 80-100m² per 40HQ

MOQ: 100m² (smaller trial orders available)

Global logistics support with project documentation

The 2025 New Design Catalog is here!

Download now to explore the 2025 design trends and bring fresh inspiration to your home!