Zero silica quartz vs quartz stone presents a clear difference in physical performance and health safety. Recent laboratory data shows that zero silica quartz matches or exceeds traditional quartz stone in hardness, strength, and stain resistance.

Performance Indicator | Zero Silica Quartz | Traditional Quartz Stone |

|---|---|---|

Mohs Hardness | 5-7 | |

Flexural Strength (MPa) | Up to 84.2 | Around 52.7 |

Water Absorption | <0.02% | Slightly higher |

Silica content plays a critical role in worker health. Studies confirm that high crystalline silica levels can cause severe lung disease. Durability, safety, maintenance, cost, and application suitability all influence the choice between zero silica quartz vs quartz stone.

Key Takeaways

Zero silica quartz offers similar or better hardness and durability than traditional quartz stone while reducing health risks from silica dust.

Zero silica quartz uses recycled materials and safer manufacturing, making it more eco-friendly and better for worker safety.

Both materials resist scratches, stains, and heat well, but using trivets protects surfaces from hot pans.

Cleaning zero silica quartz and quartz stone is easy with mild soap and water, requiring no sealing or special maintenance.

Zero silica quartz usually costs more but provides added value through safety, sustainability, and long-term performance.

Zero silica quartz vs quartz stone: Key Differences

Composition

Zero silica quartz and traditional quartz stone differ most in their core ingredients. Traditional quartz stone contains about 90-95% ground natural quartz. This means it has a very high silica content. Silica is a mineral that can cause health problems when workers breathe in dust during cutting or processing. Zero silica quartz, on the other hand, contains less than 5% silica. Some products may have up to 10%, but this is still much lower than traditional quartz stone. Manufacturers use alternative materials such as recycled glass, ceramics, and advanced resins. These changes in composition help to remove the risk of harmful silica dust. Both materials keep strong structural qualities and attractive appearances.

Note: The absence of crystalline silica in zero silica quartz makes it much safer for workers and users.

Manufacturing

The manufacturing process for zero silica quartz vs quartz stone shows clear differences. Traditional quartz stone production starts with mining natural quartz. Workers crush, clean, and process the quartz into fine particles. Factories mix these particles with resin and pigments, then press and cure the mixture to form slabs. This process releases silica dust, which can harm workers’ lungs.

Zero silica quartz uses a different approach. Manufacturers collect recycled glass and ceramics, clean them, and grind them into fine sand. They mix these materials with advanced resins and pigments. The mixture goes through pressing and curing, similar to traditional quartz stone. However, the process does not release dangerous silica dust. This makes the workplace safer. The use of recycled materials also reduces the need for mining and lowers industrial waste. Energy consumption drops because recycled glass and ceramics require less processing than natural quartz.

Aspect | Traditional Quartz Stone | Zero Silica Quartz |

|---|---|---|

Main Ingredient | Natural quartz (high silica) | Recycled glass, ceramics |

Silica Content | 90-95% | <5% (sometimes up to 10%) |

Health Risk | Silica dust exposure | No silica dust |

Environmental Impact | Mining, dust pollution | Eco-friendly, less waste |

Zero silica quartz vs quartz stone shows that the choice of raw materials and manufacturing methods affects both safety and environmental responsibility. Manufacturers who use zero silica quartz help protect workers and support sustainable practices.

Performance

Hardness

Hardness measures how well a surface resists scratching and denting. Both traditional quartz stone and natural quartz rate at 7 on the Mohs scale. This means they can withstand most daily wear and tear in kitchens and bathrooms. Zero silica quartz, made with recycled glass and advanced resins, also achieves a high level of hardness. Most zero silica quartz surfaces reach between 6 and 7 on the Mohs scale. This places them close to traditional quartz stone in terms of scratch resistance.

Material | Mohs Hardness |

|---|---|

Natural Quartz | 7 |

Quartz Stone | 7 |

Zero Silica Quartz | 6-7 |

A countertop with a Mohs hardness of 6 or above resists scratches from knives, keys, and other common objects. Both materials provide strong protection against everyday damage.

Durability

Durability describes how long a material lasts and how well it stands up to heavy use. Both zero silica quartz and traditional quartz stone offer excellent durability. These surfaces resist scratches, chips, and stains, making them suitable for busy kitchens and bathrooms. Zero silica quartz is engineered to improve impact resistance. This means it is less likely to chip or crack if something heavy falls on it.

Quartz stone also performs well in daily use. However, some users report that edges may chip if struck with force. Both materials are non-porous, so they do not absorb liquids or stains easily. This quality helps them stay clean and look new for many years.

Tip: Both zero silica quartz and quartz stone surfaces require little maintenance. Regular cleaning with mild soap and water keeps them in top condition.

Resistance

Resistance covers several important qualities, including scratch resistance, stain resistance, heat resistance, and density.

Scratch Resistance: Both materials resist scratches from most household items. Their high Mohs hardness ensures that knives and utensils do not leave marks.

Stain Resistance: Zero silica quartz and quartz stone are non-porous. Spills from coffee, wine, or oil do not penetrate the surface. Quick cleaning prevents any lasting stains.

Heat Resistance: Quartz stone contains resin, which can be sensitive to high temperatures. Placing hot pans directly on the surface may damage the resin and cause marks. Zero silica quartz also uses resin, so it is best to use trivets or mats for hot cookware. Both materials handle normal kitchen heat but should avoid direct contact with very hot objects.

Density: Both surfaces are dense and solid. This makes them strong and less likely to absorb water or develop cracks.

A quick comparison of resistance features:

Feature | Zero Silica Quartz | Quartz Stone |

|---|---|---|

Scratch | High | High |

Stain | High | High |

Heat | Moderate | Moderate |

Density | High | High |

Zero silica quartz vs quartz stone shows that both materials deliver strong performance in daily use. Each offers a reliable, long-lasting surface for homes and businesses.

Safety

Silica Dust

Crystalline silica dust is a serious health hazard in the stone industry. When workers cut, grind, or polish traditional quartz stone, they release fine silica dust into the air. These tiny particles can enter deep into the lungs. Many studies show that breathing in this dust can cause silicosis, a lung disease that leads to breathing problems and, in severe cases, death. Other risks include lung cancer and long-term respiratory issues.

Silicosis can develop quickly or over many years, depending on exposure.

Engineered quartz stone contains up to 93% crystalline silica, much higher than natural stone.

Most dust particles are smaller than 2.5 microns, making them easy to inhale.

Many workplaces do not have enough ventilation or dust control.

Air samples often show silica dust levels above safe limits.

Cases of silicosis have been reported in several countries, showing the global scale of the problem.

Note: Zero silica quartz does not contain crystalline silica. This means workers do not face the same risks from dust during fabrication or installation.

Workplace Safety

Workplace safety rules for traditional quartz stone are strict. Employers must use engineering controls such as ventilation, water-injected tools, and dust extraction systems. Workers need personal protective equipment like respirators and protective clothing. Regular air monitoring and training are also required. These measures aim to keep silica dust below legal limits and protect worker health.

Aspect | Traditional Quartz Stone | Zero Silica Quartz |

|---|---|---|

Crystalline Silica Content | Up to 90% | |

Health Risks | High risk of silicosis and lung damage | Minimal to none |

Safety Controls Needed | Reduced or not required | |

Regulatory Oversight | Strict (OSHA, local laws) | Lower due to low silica |

Zero silica quartz vs quartz stone shows a clear difference in workplace safety. Zero silica quartz eliminates the need for many of these controls, making the work environment safer and easier to manage. Many countries now encourage or require the use of low-silica or silica-free materials to protect workers.

Maintenance

Cleaning

Quartz stone and zero silica quartz both offer easy cleaning routines. Their nonporous surfaces do not require sealing, which sets them apart from natural stone. Homeowners can keep these surfaces looking new with simple daily care.

Wipe the surface with a damp cloth and mild soap or a non-abrasive cleaner.

Use denatured alcohol or window cleaner with a 100% white cotton paper towel for a streak-free finish.

Avoid plant oil-based cleaners, as these can leave a residue.

For stubborn spots, apply a soft scrub to a small area, then rinse with water.

Prevent scratches by using cutting boards and avoid abrasive materials like sand or silica.

Do not use strong chemicals such as bleach, acetone, or oven cleaners.

Place hot pans on trivets or mats to protect the surface from heat damage.

Manufacturers recommend regular cleaning with products such as diluted vinegar, Simple Green, or non-abrasive multi-surface cleaners. Quartz surfaces resist stains from most household items, but prompt cleaning of highly staining products like red wine helps maintain their appearance. Both materials do not require sealing, which reduces maintenance time and cost.

Tip: Downloadable care guides from manufacturers provide detailed instructions for specific products.

Longevity

Quartz stone and zero silica quartz both deliver impressive longevity. Their hard, dense surfaces resist scratches and stains, making them ideal for busy kitchens and bathrooms. Maintenance remains simple over the years, with only occasional professional polishing needed for older surfaces to restore shine.

Maintenance Aspect | Quartz Stone & Zero Silica Quartz | Natural Stone (Granite) |

|---|---|---|

Sealing Requirement | Every 6–24 months | |

Daily Cleaning | Warm water, mild soap | Warm water, mild soap |

Maintenance Frequency | Low | Higher |

Maintenance Cost | Lower | Higher |

Major brands offer long warranty periods for quartz products, often ranging from 10 years to a lifetime for residential use. This reflects the confidence manufacturers have in the durability and performance of both zero silica quartz and traditional quartz stone. Their low-maintenance nature and robust warranties make them a practical choice for modern homes.

Cost

Price

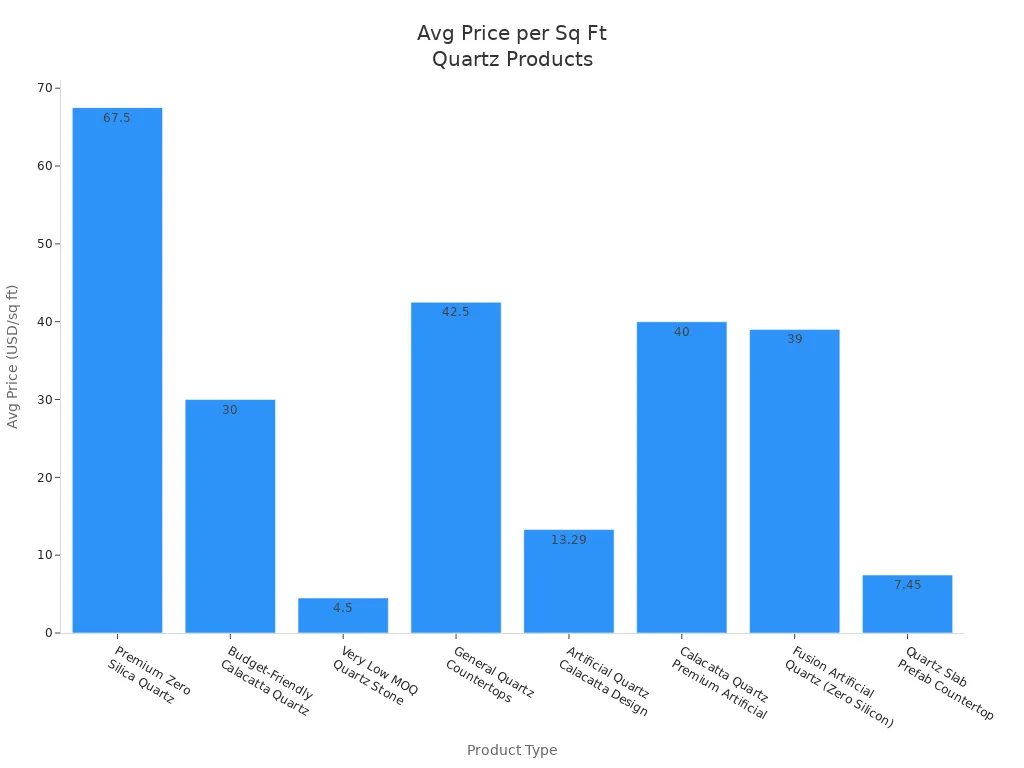

The price of quartz surfaces varies based on quality, design, and supplier. Zero silica quartz often sits at the higher end of the market due to its advanced materials and safer production methods. Traditional quartz stone offers a wider price range, making it accessible for different budgets.

Product Type / Description | Price Range (per sq ft) | Notes / MOQ (Minimum Order Quantity) |

|---|---|---|

Premium Zero Silica Quartz / Calacatta Quartz Slabs | MOQ: 100-200 sq metres | |

Budget-Friendly Calacatta Quartz Options | $20 – $40 | MOQ: 20-50 sq metres |

Very Low MOQ Quartz Stone | $4 – $5 | MOQ: as low as 100 sq ft |

General Quartz Countertops | $15 – $70 | Market average range |

Artificial Quartz Stone with Calacatta Design | $9.30 – $17.28 | MOQ: 100 sq ft |

Calacatta Quartz Premium Artificial Quartz | $20 – $60 | MOQ: 50 sq metres |

Fusion Artificial Quartz (Zero Silicon & Low Silica) | $38 – $40 | MOQ: 250 sq metres |

Quartz Slab Prefabricated Countertop Grey Vein Quartz | $5.95 – $8.95 | MOQ: 1000 sq ft |

Quartz countertops in the current market generally range from $15 to $70 per square foot. White quartz often costs more because of its rarity and popularity. Zero silica quartz usually carries a 10–15% premium over traditional quartz stone.

Value

Zero silica quartz and traditional quartz stone both offer strong value, but their benefits differ. Zero silica quartz stands out for its health and environmental advantages. It eliminates silica dust exposure, making the workplace safer. Manufacturers use recycled materials, which supports sustainability and reduces pollution.

Factor | Zero Silica Quartz (Silica-Free) | Traditional Quartz Stone |

|---|---|---|

Health & Safety | Eliminates silica dust exposure, reducing risk of silicosis | Contains high silica content, risk of silica dust inhalation during manufacturing |

Environmental Impact | Eco-friendly, uses recycled materials | Less emphasis on sustainability |

Durability | Comparable stain, scratch, and heat resistance | High durability |

Aesthetic Versatility | Wide range of colours and finishes | Diverse colours and finishes |

Maintenance | Easy to maintain, non-porous | Similarly low maintenance |

Cost | Often carries a 10–15% premium | Generally less expensive |

Manufacturing Safety | Safer work environment | Exposure to silica dust poses health risks |

Long-term Value | Potentially better sustainability and resale impact | Established market value |

Quartz surfaces, including zero silica quartz, help increase property resale value. Buyers appreciate their durability, low maintenance, and stylish appearance. These qualities make quartz countertops a smart investment for homes and businesses.

Tip: Choosing zero silica quartz supports a safer environment and may enhance long-term property value.

Applications

Residential

Homeowners often choose zero silica quartz and quartz stone for indoor surfaces. These materials appear in kitchens as countertops and islands, in bathrooms as vanities, and in laundry rooms as worktops. People also use them for built-in desks, mudroom benches, and custom tabletops. Both materials offer durability, stain resistance, and moisture protection. Cleaning remains simple, as the surfaces do not absorb liquids or require sealing.

Zero silica quartz provides extra safety by removing crystalline silica, which makes it a popular choice for families who value health and sustainability. Some advanced zero silica quartz products, such as Bioquartz®, match the performance of traditional quartz stone. These surfaces resist scratches and stains, keeping their appearance for many years. Solid surface silica-free materials offer easy repair if damaged, though they may have lower heat resistance. Low silica quartz balances safety and proven reliability, giving homeowners peace of mind.

Note: Quartz materials are not suitable for outdoor use because sunlight can cause fading or discolouration.

Commercial

Businesses in hospitality and retail settings rely on zero silica quartz and quartz stone for high-traffic areas. These materials appear in hotel lobbies, restaurant bars, reception desks, and public washrooms. Their non-porous surfaces resist stains and germs, which helps maintain hygiene in food service and healthcare environments.

Feature | Benefit in Commercial Use |

|---|---|

Silica-Free Composition | Enhances safety by eliminating silica dust exposure |

Fire Resistance | Meets or exceeds commercial fire safety codes |

Water Resistance | Prevents mould and moisture damage |

Anti-Microbial | Maintains hygienic surfaces in public spaces |

Durability | Resists scratches and daily wear |

Heat Resistance | Withstands high temperatures in kitchens |

Maintenance | Reduces cleaning time and costs |

Service Life | Provides long-term value (30+ years) |

Many commercial projects choose these surfaces for their style, eco-friendly content, and ease of fabrication. Advanced manufacturing ensures consistent quality and a seamless look. Zero silica quartz, in particular, supports safer workplaces and sustainable building practices, making it a smart choice for modern businesses.

Choosing the Right Material

User Needs

Selecting the right surface depends on several factors. Each project has unique requirements. Users should consider how the material will perform in daily life. Some people need a surface that resists stains and scratches. Others want a product that supports health and safety. Many homeowners and business owners look for materials that match their style and budget.

A table below summarises common user priorities:

Priority | Description |

|---|---|

Durability | Withstands daily wear, scratches, and stains |

Safety | Reduces health risks for workers and users |

Maintenance | Requires simple cleaning and care |

Cost | Fits within budget constraints |

Sustainability | Supports eco-friendly practices |

Aesthetic Appeal | Offers colours and patterns to suit design needs |

People in regions with strict regulations, such as Australia, must choose surfaces with very low or zero silica content. Families often prefer materials that do not release harmful dust. Designers and architects may focus on appearance and long-term value. Businesses need surfaces that last in high-traffic areas.

Tip: Users should check product labels and technical data sheets to confirm silica content and performance features.

Zero silica quartz vs quartz stone shows clear differences in safety, durability, and cost. Zero silica quartz offers a safer choice for workers and supports eco-friendly practices. Quartz stone provides proven strength and value. Buyers should consider health, long-term performance, and budget before making a decision. Those seeking more information can explore resources such as manuals, educational programmes, and industry events.

Resource Type | Description |

|---|---|

Resource Library | A comprehensive collection of publications and documents related to natural stone and quartz stone. |

Educational Programmes | Natural Stone University, CEU courses, live webinars, silica training, and safety courses. |

Manuals and Guides | Dimension Stone Design Manual, Supplier-to-Buyer Manual, and other technical publications. |

Events and Summits | Fabricator Stone Summits, Quarrier Stone Summits, and other industry events. |

Additional Resources | Natural Stone Catalogue, Building Stone Magazine, Spanish Resources, and internship resources. |

FAQ

What makes zero silica quartz safer than traditional quartz stone?

Zero silica quartz contains almost no crystalline silica. Workers do not breathe in dangerous dust during cutting or installation. This reduces the risk of lung diseases such as silicosis.

What zero silica quartz pattern or designs are available ?

Due to the continuous efforts of G-Stone team, we can produce all the zero silica quartz in the same designs as the traditional or standard quartz stone slabs.

Is zero silica quartz more expensive than quartz stone?

Zero silica quartz usually costs more. The advanced materials and safer production methods increase the price. Many buyers see value in the health and environmental benefits.

How do I clean zero silica quartz or quartz stone?

Use a soft cloth with mild soap and water. Avoid harsh chemicals or abrasive pads. Both surfaces resist stains and do not need sealing.

Where can zero silica quartz be used?

People use zero silica quartz in kitchens, bathrooms, and commercial spaces. It suits worktops, vanities, and reception desks. The material offers durability and safety in many settings.